Are you constantly experiencing water leaks or damage to electrical equipment because you’re not sealing your cable ducts properly?

If you don’t seal your cable ducts properly, water and moisture can get in and cause electrical failures, damage your equipment, and even create safety issues. If you don’t seal them right, your cables can also get exposed to dust, debris, and temperature changes, which will mess up your systems and make them not work right.

You don’t want to deal with costly repairs or unexpected downtime caused by poor sealing systems.

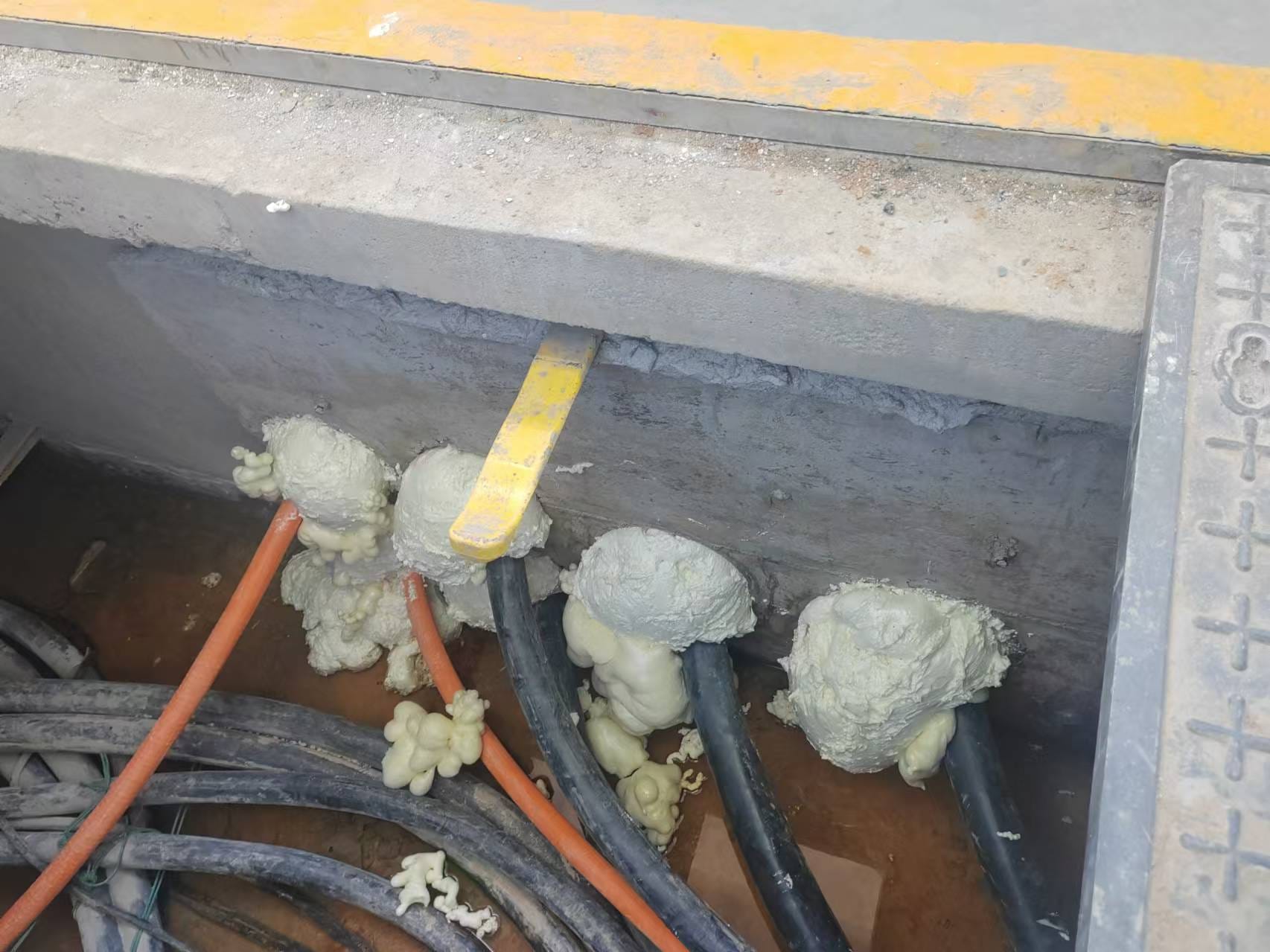

Traditional sealing methods, like foam or basic sealants, often fail under pressure or aren’t resistant to environmental factors like moisture, chemicals, or fire. These ineffective solutions can deteriorate over time, causing more severe damage. You need a reliable solution to keep problems from happening in the first place.

Solution:That’s where modern cable duct seals and sealing systems come in. These advanced systems provide long-lasting protection, keeping your cables safe from water, fire, and other elements that can cause damage.

What Are Cable Duct Seals & Sealing Systems?

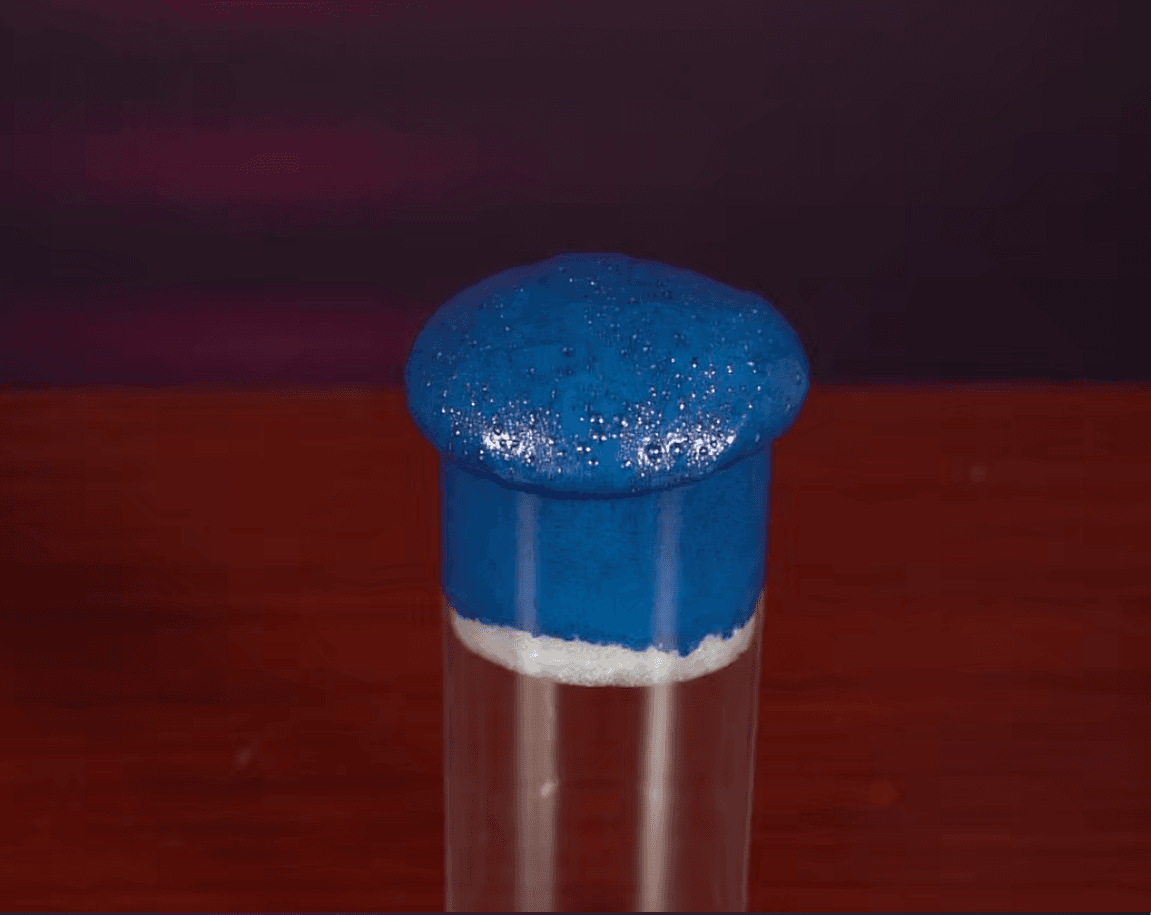

Cable duct seals and sealing systems are specially designed solutions that protect cable penetrations from water, dust, gases, and other environmental hazards. These systems are used to make sure cables running through walls, floors, or underground ducts stay watertight, fire-resistant, and durable. The seals are usually made of high-performance materials, like polyurethane or rubber compounds, designed to block leaks and make sure cable penetrations stay intact even in extreme conditions.

Modern cable duct sealing systems solve a bunch of problems: they can handle high pressure, keep water out, protect against fire, and can be customized to fit different sizes of ducts and cables. They’re also easy to install, which makes them a good choice for both small and big engineering projects.

Curious about how these cable duct sealing systems work, or what makes them so effective?

In this post, we’ll tackle the most frequently asked questions on cable duct seals, from their benefits to the installation process and materials used. We hope that by answering these questions, we’ll help you make the best decision for your application.

Common Questions About Cable Duct Seals & Sealing Systems

1. Why is it important to seal cable ducts properly?

It’s important to seal cable ducts properly because if you don’t, water can get in, causing your cables to corrode and short out. If you’re in a high-risk environment, you also need to make sure your seals are fire-resistant. If you have a failure in a seal in a high-risk environment, you could have a catastrophe on your hands. So, you need to make sure you have a good seal to protect your systems from water and fire.

2. What materials are used in cable duct seals?

Cable duct seals are made out of materials that can handle the environment they’re in. They’re made out of things like polyurethane, EPDM rubber, and silicone. These materials are flexible, waterproof, and can handle UV radiation, chemicals, and extreme temperatures. Polyurethane is also very strong, so it’s good for watertight seals that also need to be fire-resistant.

3. How does the installation process work?

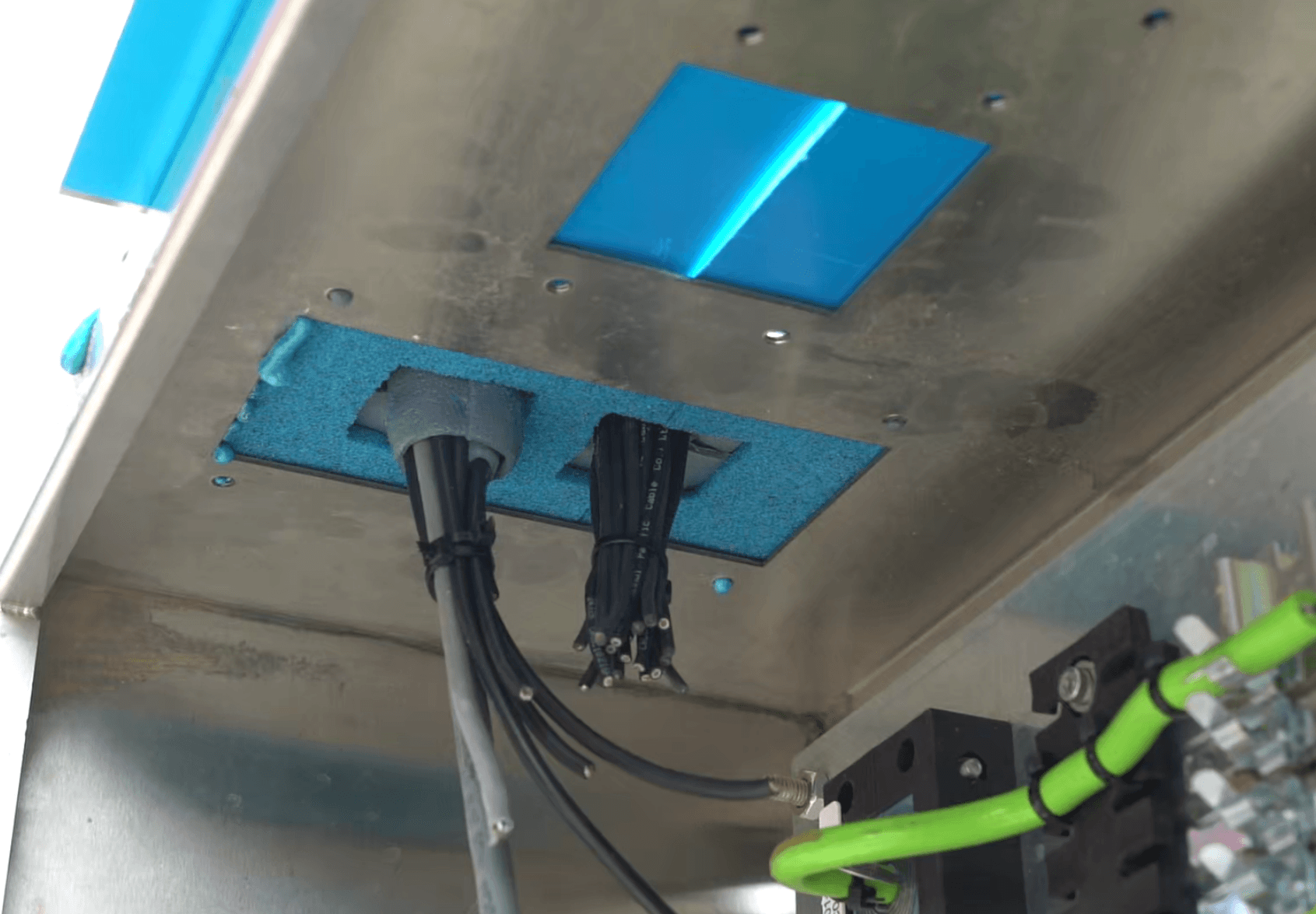

You can use sealing foams or compounds to fill the gaps and make a good seal. You can use them when you first put in the pipe or you can go back and put them in later if you have to fix up an old pipe.

4. What are the benefits of using cable duct sealing systems?

There are a lot of benefits to using cable duct sealing systems. They keep water out of your ducts, so your cables and equipment don’t get damaged. They’re fire-resistant, so they protect your cables in case of a fire. Some of them are also rodent- and pest-resistant, so you don’t have to worry about rodents chewing on your cables. They can handle pressure, so if you have a high-pressure environment, like a basement or an underwater tunnel, you don’t have to worry about leaks. They’re customizable, so you can get the right size and shape for your ducts. They’re easy to install, so you don’t have to spend a lot of time on them.

5. Where are cable duct seals typically used?

Cable duct seals are used in a lot of different industries. They’re used in telecommunications and data centers to keep cables safe from water and fire. They’re used in power generation facilities to protect the cables that transmit power. They’re used in construction projects to keep water out of your ducts and prevent structural problems. They’re used in petrochemical plants to keep chemicals from leaking out and causing fires.

6. Can cable duct sealing systems be customized?

Yes, cable duct sealing systems can be customized. You can get them in different sizes for different cable diameters. You can get them in different shapes for different penetrations. You can get them in different materials for different environments.

SafelySeal’s Cable Duct Seals & Sealing Solutions

At SafelySeal, we offer high-quality products designed for watertight, fire-resistant, and pressure-resistant sealing solutions for various industries:

- Watertight Cable Ducts and Pipe Penetrations: Our polyurethane seals offer superior water resistance, blocking leakage even under high-pressure environments such as basements or tunnels.

- Polyurethane Pipe and Cable Sealant: Provides strong adhesion, is UV-resistant, and is highly durable, perfect for long-lasting protection.

- Solutions for Sealing in Wet Environments: Our seals are designed to perform in waterlogged or damp conditions, offering fire resistance, compression strength, and durability.

- Cable Tunnel and Floor Sealing Solutions: Specialized systems for protecting cables in challenging environments like underground tunnels and floors prone to water infiltration.

- Cable Routing Device Seals: Perfect for ensuring cables routed through walls, switchboards, or cabinets are safely sealed against water and other elements.

So, to sum it all up, cable duct seals and sealing systems are a good way to keep your cables safe from water, fire, and other things that can hurt them. If you use the right stuff and put it in the right way, you can keep your wires working good for a long time. That’s why you should get some of our stuff if you have a project where you need to seal up some cables.