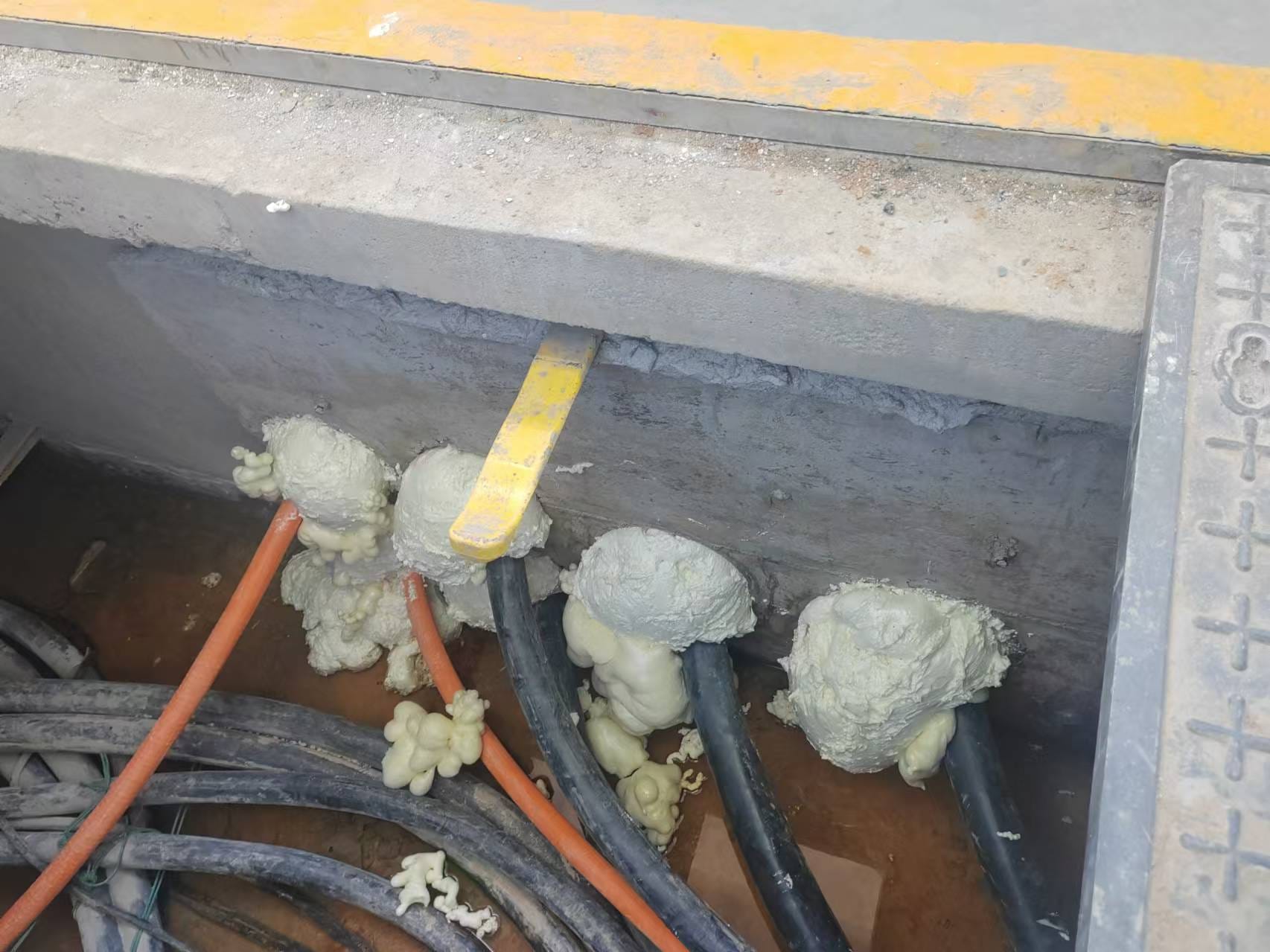

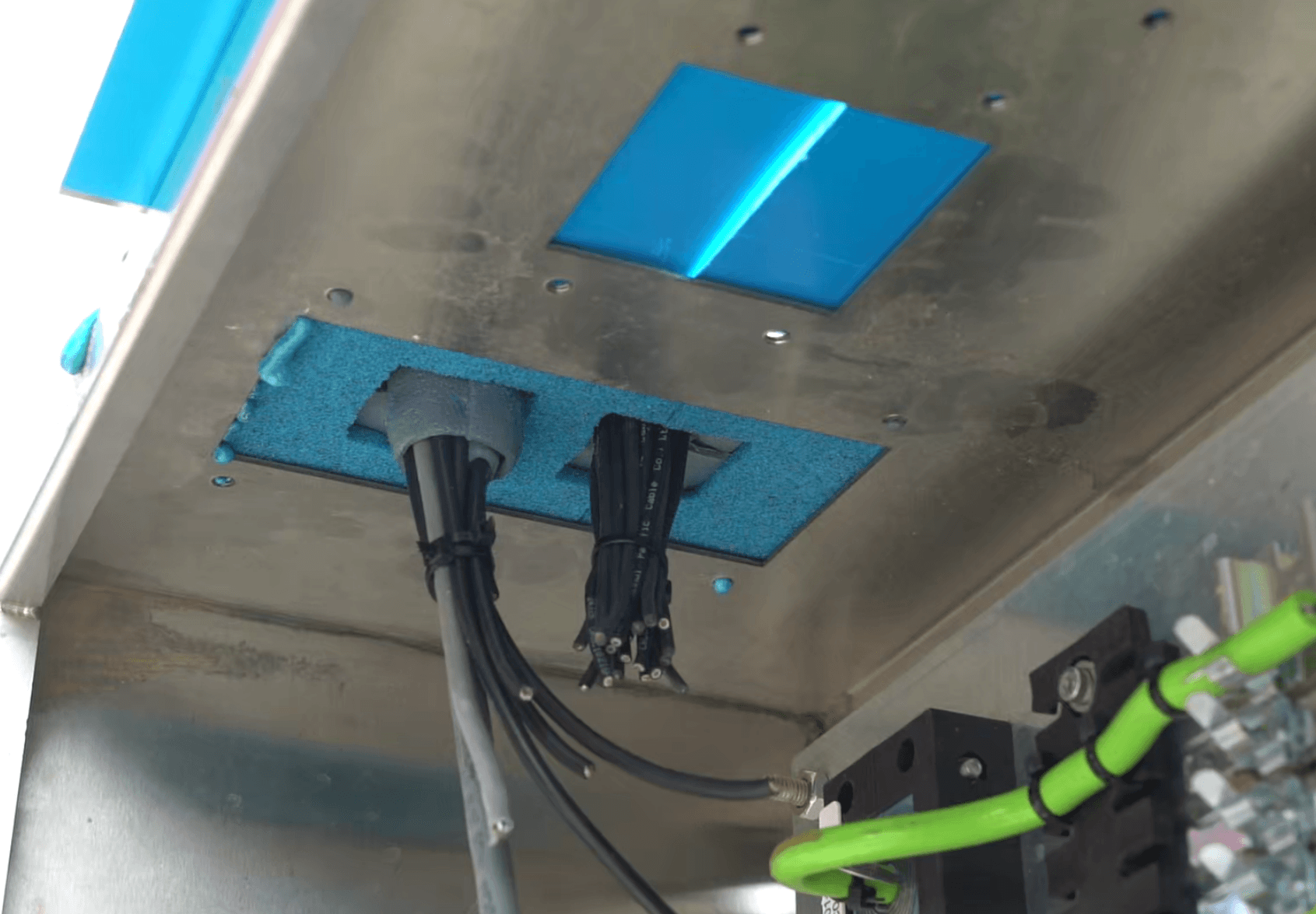

When you’re in construction or engineering, you need to know your materials. When water gets into poorly sealed cable penetrations, it can cause major problems for electrical systems, costing you a lot of money and downtime. Traditional foam sealants can’t handle the pressure, so they either get squished or washed away, and then you’re in big trouble. What if you had something that could handle the pressure and also give you a great waterproof and fire-resistant seal? That’s what our product does. It has a compressive strength of 2.26 MPa, so it can handle the toughest environments.

Compressive Strength: A Key Property

Compressive strength is the ability of a material to withstand loads that tend to reduce its size. It is measured by the maximum amount of compressive stress that a material can handle before it fails. This is important for materials used in construction, like concrete, metal, and sealants, because it tells you how much weight they can bear and how well they can resist being squished or cracked when you put pressure on them. If something has a high compressive strength, it means it can hold up and do its job even when you put a lot of weight on it.

Why Should You Care About Compressive Strength?

Compressive strength is a fundamental property that directly impacts the durability and reliability of materials used in construction and engineering projects. For cable penetration sealants, high compressive strength means better resistance to groundwater pressure, preventing leaks and ensuring long-term protection of electrical equipment. This translates to reduced maintenance costs, increased safety, and uninterrupted operations.

What is the significance of compressive strength in construction materials?

Compressive strength is important in construction because it tells you how well a material can handle loads without breaking or changing shape. It’s what keeps buildings and bridges from falling down and helps them last a long time.

How is compressive strength measured?

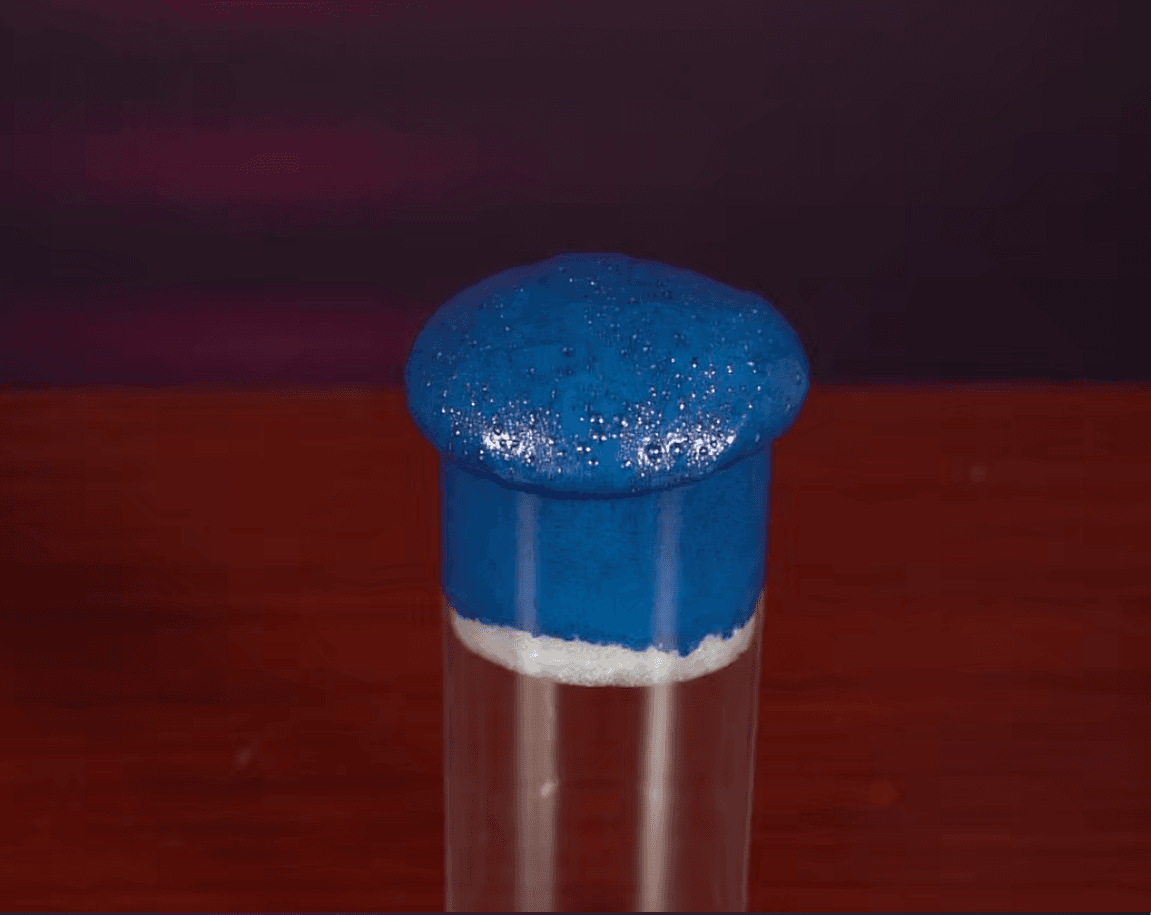

Compressive strength is typically measured using a universal testing machine, where a sample material is subjected to controlled compression until it fails. The maximum stress the material can withstand before failure is recorded as its compressive strength, usually expressed in megapascals (MPa) or pounds per square inch (psi).

What are common materials with high compressive strength?

To measure compressive strength, you use a machine that can squish stuff. You put the material you want to test in the machine and push on it until it breaks. The highest amount of pressure the material can handle before it breaks is its compressive strength. People usually measure compressive strength in units called megapascals (MPa) or pounds per square inch (psi).

How does our product’s compressive strength compare to traditional foam sealants?

Our product has a compressive strength of 2.26 MPa, which is a lot stronger than regular foam sealants. Regular foam sealants can’t handle the pressure from water pushing on them from the outside. Our sealant is strong enough to stay in place and keep working, so you get a great waterproof and fire-resistant seal.

What additional benefits does our sealant offer besides high compressive strength?

Our sealant has a lot of other great features, too. It sticks really well, so it stays in place and does its job. It’s fire-resistant for three hours, so it can handle a lot of heat. It’s also flame-retardant, which is the best rating you can get. Rodents and ants can’t chew through it, and it can handle being outside in the sun. It’s not bothered by acid or alkali, and it doesn’t get old and stop working. It’s a great sealant that will protect your stuff for a long time, no matter where you use it.