Table of Contents

What Is Bonding Strength?

Bonding strength refers to the measure of force or stress an adhesive bond can withstand before breaking. It is a critical property for evaluating adhesives, sealants, and coatings, especially in industries that require durability, such as construction, automotive, and electronics. Bonding strength is typically expressed in units like megapascals (MPa) or pounds per square inch (psi). Higher bonding strength indicates better adhesion and resistance to external forces like shear, tensile, or peel stresses.

This property ensures that bonded surfaces remain intact under various conditions, including exposure to water, heat, chemicals, or mechanical loads. Without sufficient bonding strength, materials may separate, leading to failures in structural integrity, waterproofing, or insulation.

What factors affect bonding strength?

- Material Compatibility: Adhesives bond better to specific surfaces; compatibility affects performance.

- Surface Preparation: Clean, dry, and roughened surfaces improve adhesion.

- Curing Conditions: Temperature, humidity, and curing time play vital roles in bond development.

- Environmental Stressors: Exposure to UV light, chemicals, or moisture can weaken bonds.

How is bonding strength measured?

To test how strong a bond is, you use standardized tests like tensile, shear, and peel tests. These tests apply a controlled amount of force to a bonded joint until it breaks, so you can see how much stress the bond can take. Some common standards are ASTM D1002 for tensile strength and ASTM D1876 for peel tests.

- Tensile strength: Tensile strength is how much a bond can handle before it pulls apart. When you’re talking about adhesives and coatings, you might hear people say “pull-off strength” instead of tensile strength because it’s easier to understand.

- Shear strength: Shear strength is how much force it takes to make bonded materials slide past each other. You use shear tests to see how strong fasteners and adhesives are.

- Peel strength: Peel strength is how much force it takes to peel two things apart. You use peel tests to see how strong adhesives like labels or tape are.

Why is bonding strength important in sealing applications?

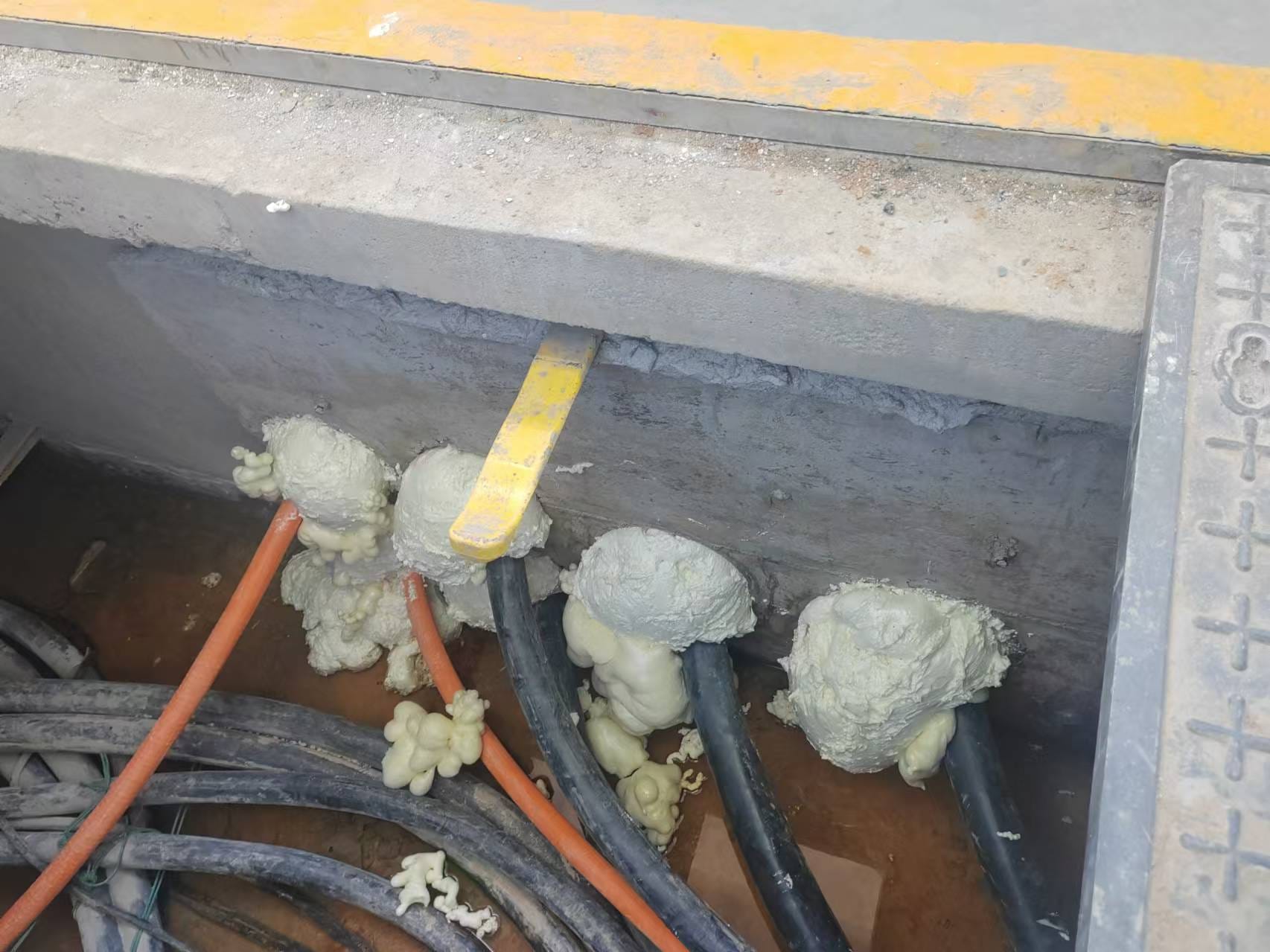

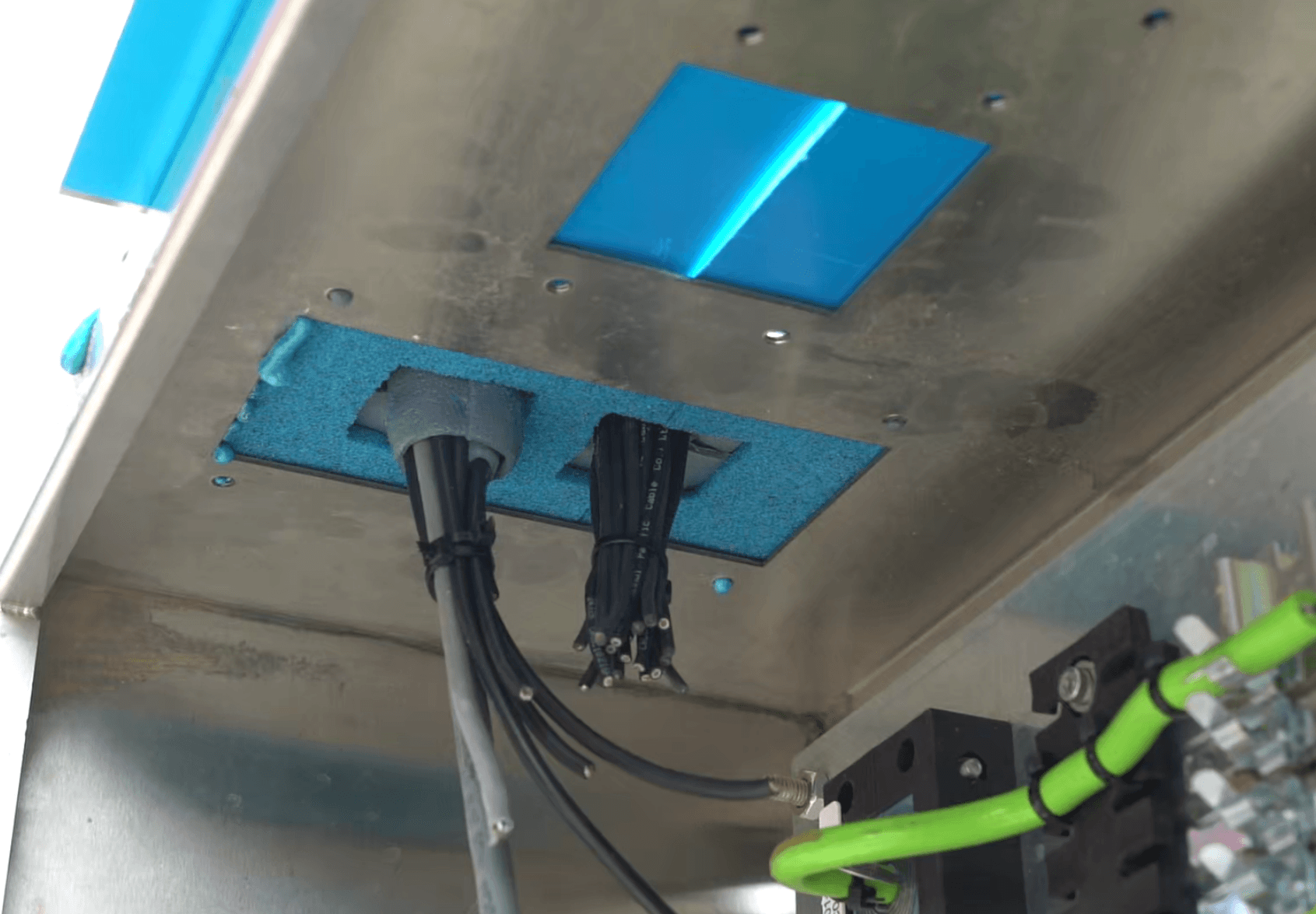

Strong bonds are important because they make sure that seals last a long time and can handle things like water getting in, temperature changes, and things bumping into them. This is especially important when you’re sealing cable ducts, pipes, and gaps in things like power plants, construction sites, or wet places.

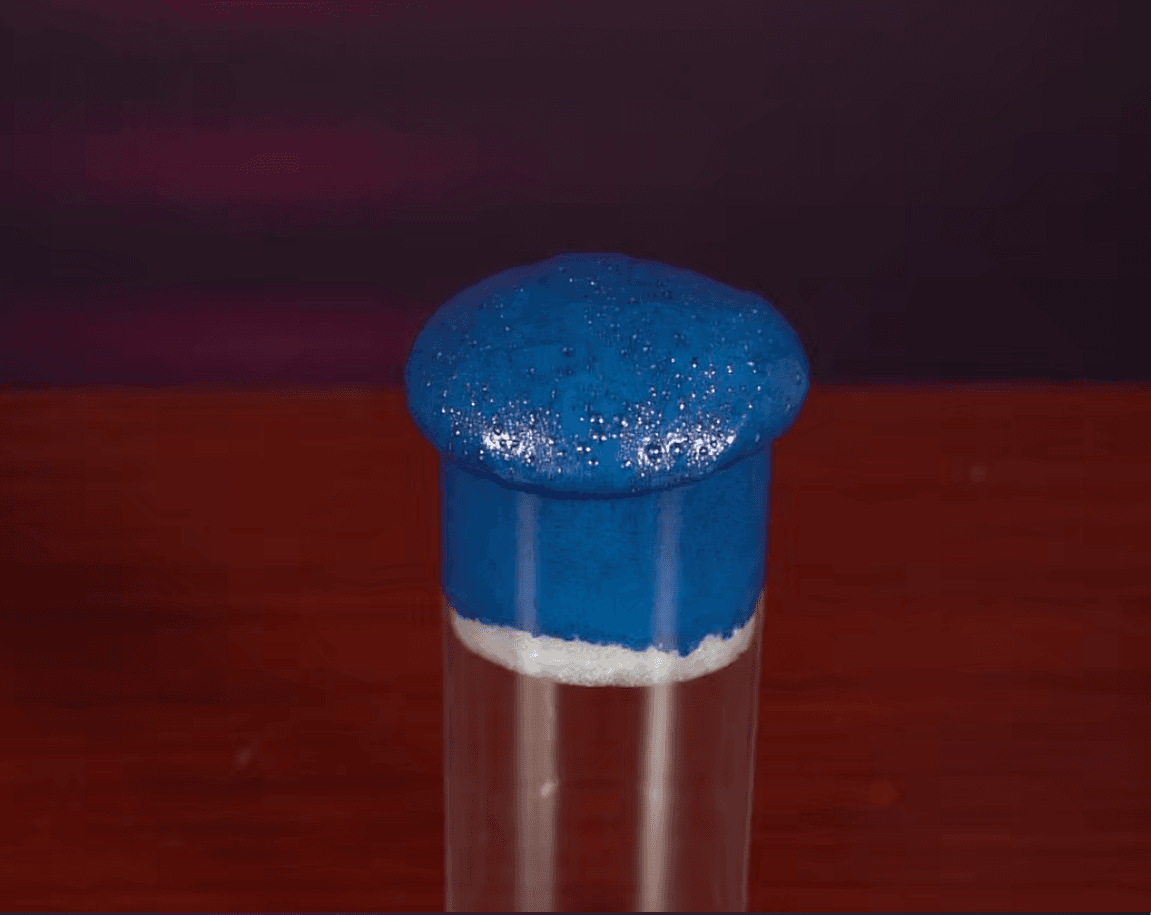

What bonding strength do SafelySeal products offer?

- Surface Preparation: Remove dirt, grease, and oxidation. Use primers if necessary.

- Correct Application: Apply adhesive evenly, following manufacturer guidelines.

- Optimize Curing: Ensure proper curing conditions, including temperature and humidity control.

Reach Out to Discuss How to Improve Bond Strength

At SafelySeal, our experts can guide you through the use of adhesives such as foaming agents. If you’re working with coatings or adhesives, get in touch to talk about what you need.