Cable entry sealing foam is a type of foam you put around the wires to keep water, air, and sometimes fire out. You squirt it around the wires, it expands, it hardens, and it keeps water, dust, bugs, and fire from getting in.

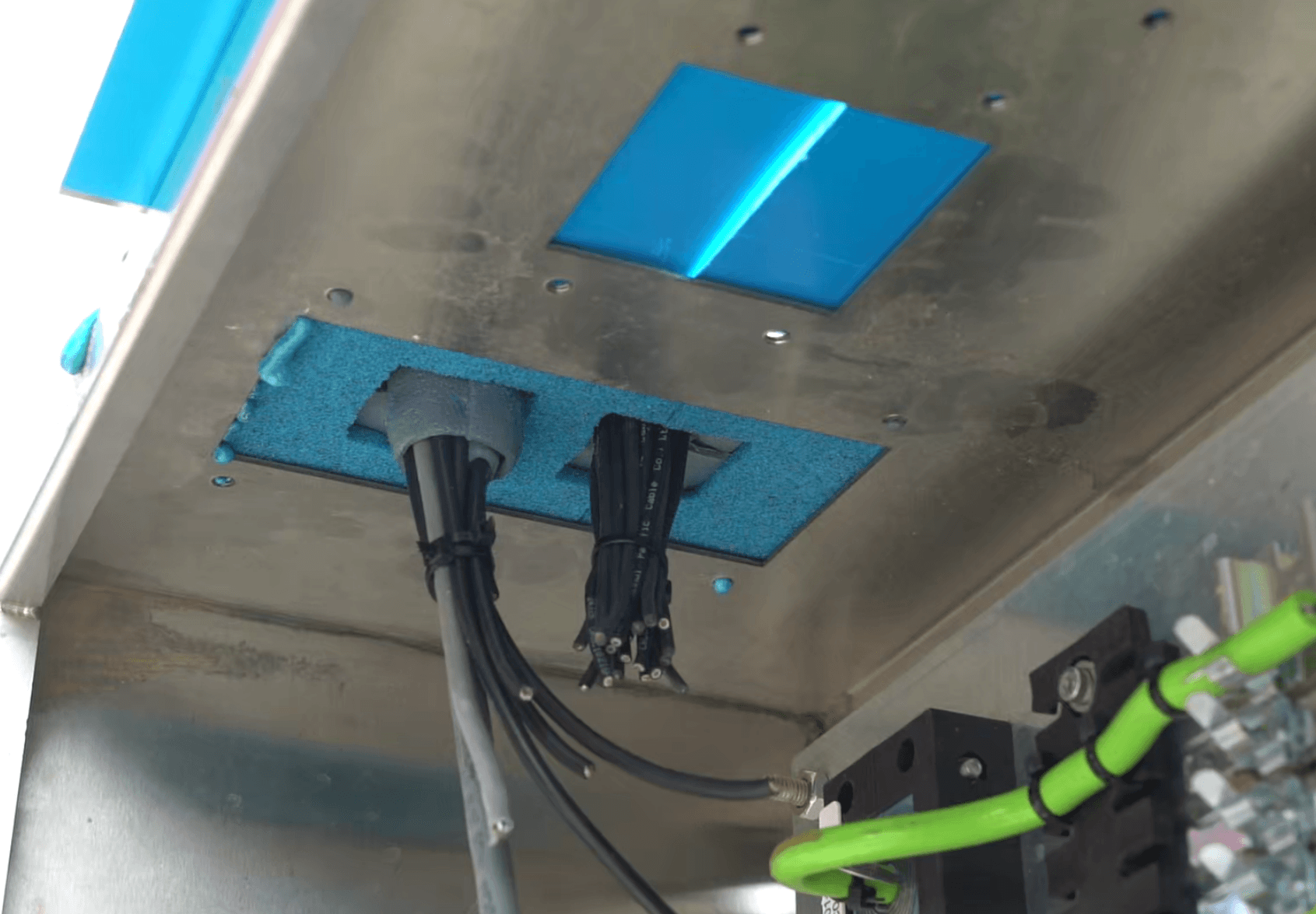

Cable entry panels is a pre-made piece that you put in the hole where the wires go through. It has slots or holes for the wires to go through. It lets you add or remove wires without having to reseal the hole, and it gives you some protection from the environment.

Let’s take a closer look at the questions most asked about cable entry sealing foam and cable entry panels.

Contents

1. How Do Cable Entry Sealing Foam and Entry Panels Work?

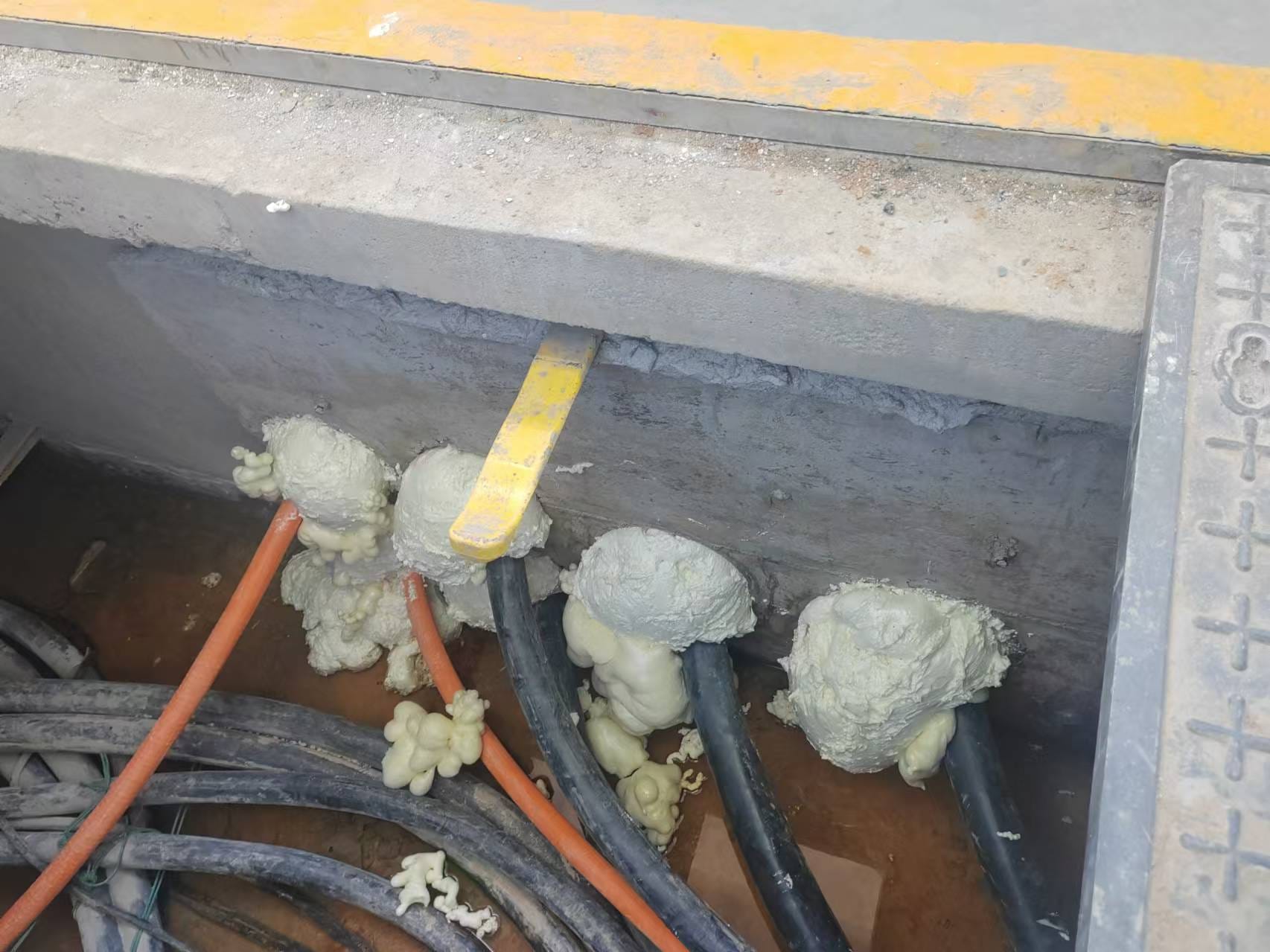

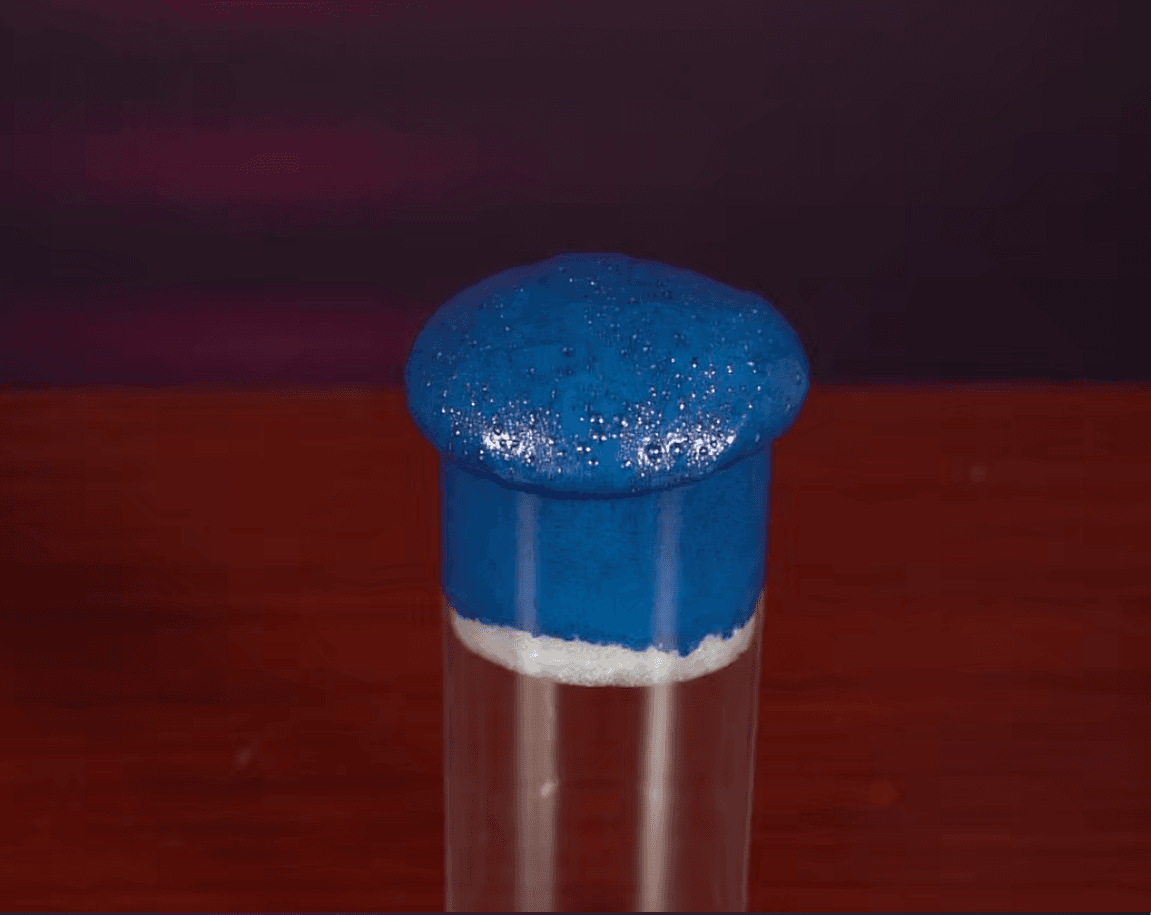

Cable Entry Sealing Foam: This foam expands around cables and hardens to fill every gap. It’s injected as a liquid or soft material that expands to tightly seal around cables, providing excellent water resistance and high-pressure tolerance. Once cured, the foam becomes a solid barrier, effective in environments where tight seals are necessary.

Cable Entry Panels: These panels are typically made from rubber or other durable materials. They contain pre-punched holes or customisable openings for cables to pass through.

2. What Are the Main Benefits of Each Solution?

Cable Entry Sealing Foam:

- Excellent Environmental Protection: Offers strong water, dust, and fire resistance, making it ideal for wet or high-risk areas.

- High Pressure Tolerance: Can withstand high pressure from water and gas, suitable for underground installations.

- Permanent Seal: Once installed, sealing foam creates a long-lasting barrier that’s challenging to breach.

Cable Entry Panels:

- Cable Management Flexibility: Easier to add or remove cables without disturbing the seal or requiring reapplication.

- Moderate Environmental Protection: While not as watertight as foam, entry panels still offer dust and moisture protection.

- Time-Efficient Installation: Entry panels simplify the process, making installation faster and convenient, especially in multi-cable setups.

3. Which Applications Are Best Suited for Each Option?

Cable Entry Sealing Foam: This option is ideal for high-risk environments that need robust protection against water, fire, or pressure. For example:

- Underground cable ducts in basements

- Power plants and industrial settings with high moisture exposure

- Electrical installations in petrochemical facilities

Cable Entry Panels: Panels are good for installations where you have to move your cables around a lot or where you don’t need a lot of protection.Common uses include:

- Server rooms and control cabinets

- Data centers with high cable traffic

- Telecommunications facilities requiring easy cable management